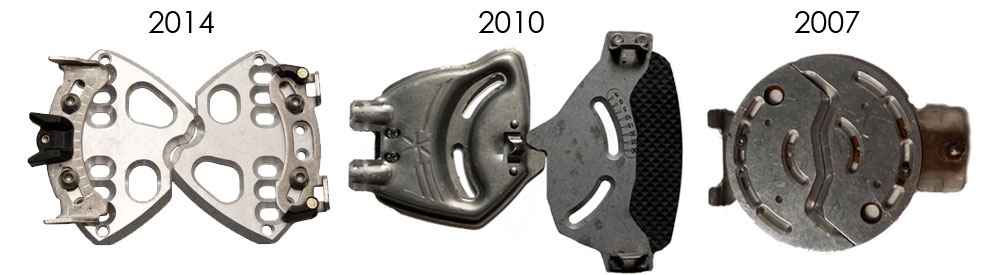

Mechanical design is funny process sometimes. You have an idea. You get stuck. You put the idea away for awhile until inspiration strikes again. You eventually come up with a solution. I’ve noticed another trend that has happened with our first release of the Split30 Splitboard System and now the PRIME Splitboard System, both designs stem from earlier designs we came up with. There was just an element we could not quite figure out with the initial designs so we went down a slightly different path. The end solution has always circled back to the initial design, sometimes it just takes six years to figure out.

In November 2007, we started designing our first splitboard system. The Ride Mode interface was based on a disk split in half that extended across the seam of the splitboard. With the PRIME Splitboard System we’ve come back to this concept and made it even better by taking lessons learned from the Split30 Splitboard System and implementing these features into the Ride Mode design. The result has been the PRIME ride mode which we call the Solid-Ride.

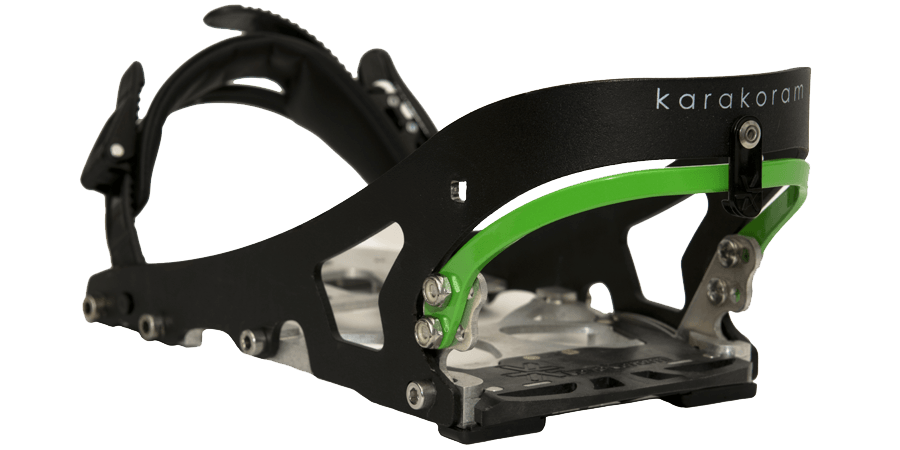

For the main improvements to the ride mode, we wanted to make splitboards ride even better than solid boards, make snow clearing easier, have the attachment to ride mode more ergonomic, have symmetric ride mode parts (-30° to 30°), and increase stance width options. The Solid-Ride increases responsiveness and power transfer at a level we couldn’t even believe. The PRIME splitboard system with Solid-Ride takes solid board feel to another level. I felt improvement on my very first turns during testing.

For snow clearing you just have to clean off the board where the binding pads touch the board and the binding falls on to the interface. Attaching the PRIME bindings is simple and powerful with the Power-Link that nests into the heelcup.

Checkout the video below to see how to clean off the interface and attach the binding.

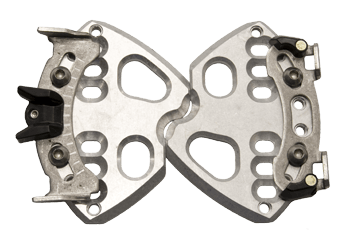

[instagram_responsive][/instagram_responsive]To make symmetric ride mode parts we went back to another feature of the 2007 design, a two piece interface with one piece fixed to the board and the other to adjust the angle.

To increase stance width options we used the multiple slot feature commonly used on standard snowboard binding disks.

When we went away from our initial 2007 design it was really tough to let it go since we had worked for two years developing it. I never really anticipated that we would leverage the design so heavily in the future, so it has been really cool to see the PRIME Splitboard System come to life sharing many design characteristics with our first prototyped concept. The old adage “there is no such thing as a bad idea” has come true here and spawned into the PRIME Splitboard System.

Now on to the next developments! I’m excited to see what the future holds. Innovation Forever.